Thanks to public and private safety organizations' efforts, many workers understand that frequent exposure to loud noise has negative health impacts; chief among these is irreversible hearing damage. Other lesser-known effects include annoyance, elevated blood pressure, stress, speech interference, and tinnitus. Welders are often exposed to hazardous noise levels due to their equipment and operations, and are at risk of occupational hearing loss.

According to the Occupational Safety and Health Administration (OSHA), noise levels over 85 decibels, averaged over an eight-hour workday, are potentially hazardous to your hearing. The OSHA standard uses a five dBA exchange rate, which means that when the noise level is increased by five dBA, the amount of time a person can be exposed to that noise level is cut in half. For example, OSHA's eight-hour permissible exposure limit (PEL) for noise is 90 dBA. If an employee were exposed to noise at an average level of 95 dBA, it would limit the allowable exposure duration to four hours (considering no hearing protection is worn).1

The Health and Safety Executive (HSE), a United Kingdom governmental agency, details the noise levels associated with different tasks within the welding process2 in the table below. Except for TIG welding, electric arc welding generates harmful levels of noise.

| Process | Typical Noise Levels |

| Tungsten Inert Gas (TIG) | Up to 75 dBA |

| Manual Metal Arc (MMA) | 85-95 dBA |

| Metal Inert Gas (MIG) | 95-102 dBA |

| Plasma cutting (hand-held up to 100 A, cutting up to 25 mm thickness only) | 98-105 dBA |

| Flame gouging | 95 dBA |

| Air arc gouging | Up to 100 dBA (typically above 90 dBA when cutting thicknesses above 1.5 inches) |

| Deslagging/chipping | 105 dBA |

| Grinding | 95-105 dBA |

Actual noise levels depend on several factors. The following factors can increase noise:

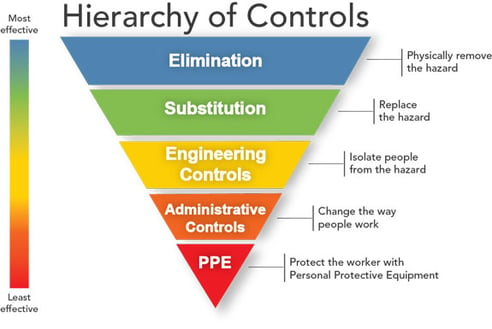

To protect workers, employers must follow the hierarchy of controls, as shown below.

Eliminating the process is not always feasible; therefore, the next best options are substitution, engineering controls, and administrative controls such as training and work scheduling. Finally, personal protective equipment (PPE) is the least effective control and should always be used as a last resort.

Eliminating the process is not always feasible; therefore, the next best options are substitution, engineering controls, and administrative controls such as training and work scheduling. Finally, personal protective equipment (PPE) is the least effective control and should always be used as a last resort.

HSE recommends the following controls, where feasible2:

This material is intended to be a broad overview of the subject matter and is provided for informational purposes only. Old Republic Contractors Insurance Group, Inc. does not endorse or recommend any products or services nor does it make any representation or warranty regarding the accuracy or completeness of the information. Old Republic Contractors Insurance Group, Inc. shall have no liability or responsibility to any person or entity with respect to any loss, action or inaction alleged to be caused directly or indirectly as a result of the information contained herein.